Maintenance Tips for your IVECO Heavy-Duty Clutch

Updated: 9th July 2025

Reviewed by IVECO-certified parts specialists

For operators of IVECO’s Heavy-Duty Range, maintaining clutch performance and durability is key to minimising operating costs.

This guide offers practical maintenance tips tailored to IVECO’s Heavy-Duty Range clutches and provides insight into the engineering behind their performance, comfort, and durability.

Why the Clutch Matters

A well-functioning clutch allows a vehicle to start smoothly, shift gears efficiently, and maintain its optimal power transmission under load. When it comes to the Heavy Duty range - where vehicles often face demanding terrain, frequent gear changes, and prolonged use - clutch performance can significantly affect operational efficiency, as well as driver comfort.

Genuine IVECO clutches are designed with these demands in mind. They not only enhance the driver’s experience by reducing vibration and noise, but also provide protection to the transmission by ensuring smooth torque delivery and minimising stress on your vehicle’s components.

Did you know?

Replacing only one component of a heavy-duty clutch system (like the disc or bearing) can shorten its lifespan. That’s because the clutch kit works as a matched system, where each part is balanced to the others to handle extreme forces without excess wear.

Core Components of the IVECO Heavy-Duty Clutch System

Understanding the function of each clutch component helps identify potential signs of wear and inform maintenance decisions.

- Clutch Disc

Constructed with high-quality friction materials on both sides, the disc ensures smooth and consistent engagement with the flywheel. The shock absorber plate’s wave design distributes pressure evenly, helping reduce judder and increase driveline protection. - Pressure Plate

This component applies the clamping force that holds the clutch disc against the flywheel. It must be properly balanced and capable of dissipating heat to prevent slippage and ensure reliable performance over time. - Thrust Bearing

Also known as the release bearing, this transfers the force from the clutch pedal via the fork to disengage the clutch. If faulty, it can cause poor gear changes and contribute to premature wear.

Practical Maintenance Tips for IVECO Heavy-Duty Clutches

While IVECO clutches are engineered for durability and high performance, regular maintenance is key to extending their service life and avoiding costly repairs. Here are a few practical recommendations:

- 1. Replace the Complete Clutch Kit

When the clutch begins to show signs of wear or underperformance, replace the full kit, not just individual components. The clutch disc, pressure plate, and thrust bearing work in tandem, and partial replacements can lead to uneven wear, reduced performance, and increased risk of repeat servicing. It is also wise to inspect and, if necessary, replace the flywheel bearing at the same time.

The IVECO team is always happy to help. If you think you need your clutch kit replaced, or simply have an enquiry

- 2. Choose Genuine IVECO Parts

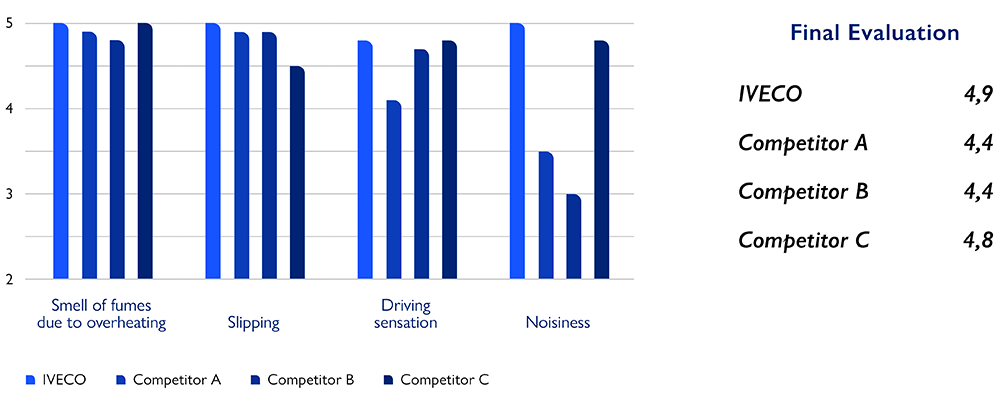

Using IVECO Genuine Parts is essential for maintaining vehicle performance. These components are manufactured to the same standards as the original equipment and undergo rigorous testing for reliability and safety. Independent tests conducted by DEKRA, a leading safety organisation, have confirmed that IVECO clutches outperform competitors in key performance areas such as durability, comfort, and thermal resistance. - 3. Monitor for Signs of Clutch Wear

Pay attention to changes in clutch feel or performance. Common signs of wear include:- Increased pedal effort

- Difficulty engaging or shifting gears

- Juddering or vibration when pulling away

- Burning smell during heavy use

- Noticeable slippage under load

- 4. Regular Inspections and Preventive Maintenance

Incorporate clutch inspections into routine maintenance schedules. For fleet operators, this can help identify issues before they escalate. Check for fluid leaks (which could affect the clutch mechanism), inspect the condition of the flywheel, and assess clutch wear indicators if accessible.

During servicing, always ask your IVECO parts specialist for advice tailored to your vehicle’s usage pattern and load conditions.

Need IVECO expertise?

Tested and Proven Performance

IVECO Heavy-Duty Range clutches have undergone a series of detailed tests in DEKRA laboratories to verify their performance under mechanical and thermal stress. These independent tests evaluated:

- Friction coefficient and surface roughness to ensure optimal torque transmission

- Chemical composition for heat and wear resistance

- Load-bearing capability and heat dissipation of the pressure plate

The results confirmed that IVECO clutches consistently deliver:

- Comfort: Smooth driving with minimal noise and vibration

- Safety: Reliable performance under load and during gear changes

- Performance: Consistent engagement without slippage

- Durability: Longer service life thanks to superior material quality

Key Takeaways

The clutch has a vital role in the performance of heavy-duty vehicles. Proper maintenance and timely replacement using Genuine IVECO parts ensure that performance, safety, and comfort are preserved even in the most demanding conditions.

For best results:

- Replace the entire clutch kit when servicing

- Only use IVECO Genuine Parts

- Stay alert to performance changes

- Seek expert advice during regular maintenance

By following these practical steps, operators can maintain optimal clutch performance, minimise disruptions, and extend the service life of their IVECO Heavy-Duty vehicles.

Request a call back below for unparalleled IVECO solutions.

Call the IVECO Parts Team

Monday to Friday 9am - 5.30pm.

Please Wait

IVECO Parts Warranties

• Best-in-class warranty. Reliability and quality certified by IVECO.

• Benefit from the same warranty as Genuine Parts. NEXPRO warranty has a life of 12 months for spare parts and 24 months for the batteries.

• Up to 3 year warranty on all our engines and gearboxes, when fitted in an approved IVECO workshop or supplied over the counter. If fitted in an approved IVECO workshop, labour is included under warranty.